A novel technology to ensure product safety, improved aromatic profile and reduced operation cost

| Technology code 21-UP-04 |

Status OPEN |

Applications mode First call for expression of interest |

Access model As specified in the call |

Code: 21-UP-04

The Opportunity

Heat treatment, the most commonly used thermal process to ensure microbial stability and safety for liquid food, is a costly process and often leads into vitamin and volatile compounds reduction and into toxic chemical compound formation. On the other hand, chemical treatment of water or wine is an effective process routinely used but associated with the presence of toxic chemical residues in the final product.

Our Offer

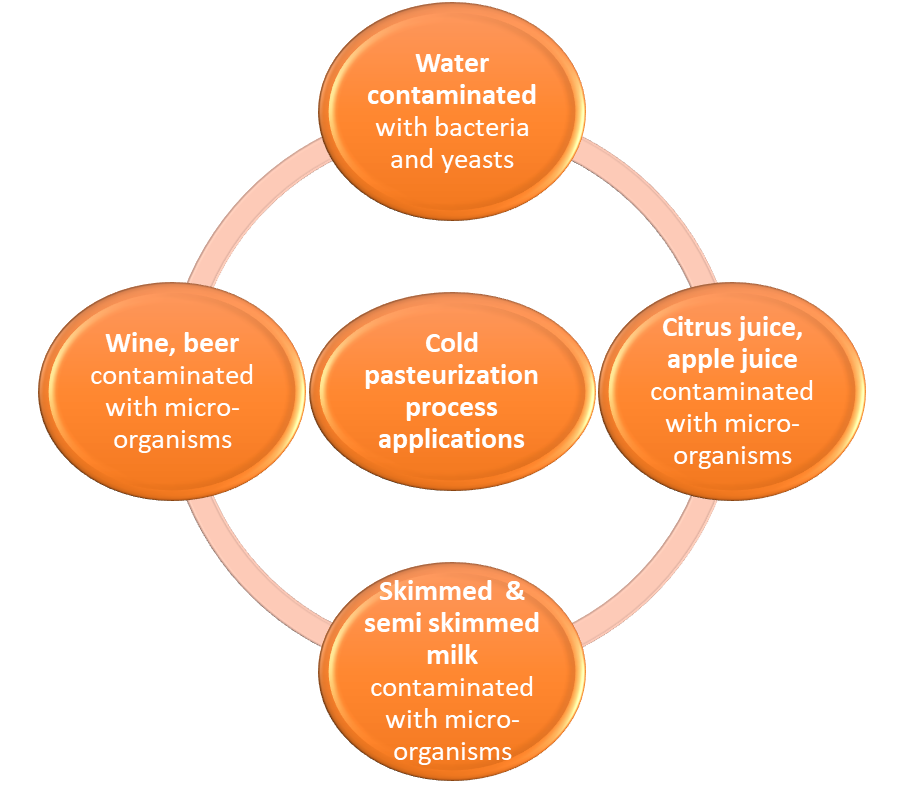

A “cold pasteurization” technology, that results in removal of microorganisms at levels up to 90-100% when applied to liquid food such as juices, wine, water and milk, has been developed by our researchers offering the food industries a means to produce safe and stable liquid food at a lower cost and with an improved nutritional and aromatic profile.

The Technology

The principle of cold pasteurization is based on the use of innovative filters that contain tubular cellulose (TC) and are organized in a parallel layout to facilitate the continuous operation of the pasteurization system.

Microbes that are present in the source liquid are entrapped in the tubes of TC and so removed from the food liquid. The TC filters can be successfully regenerated by rinsing with hot water.

Microbial load removal reached values of up to

- 90-100% when applied to apply apple juice

- 100% when applied to water

- 97% when applied to wine

- 100% when applied to orange juice

Advantages & Innovations

The technology is an innovative bioprocess that has been validated in lab environment, for liquid food such as water, fruit juices, wine, beer and milk.

- Low energy requirements

- Extension of the shelf-life of liquid foods for several days or weeks

- Products with improved nutritional value and aromatic profile

- Heat-sensitive ingredients are protected

- No use of antibacterial chemical compounds

- Low-cost investment - low operational cost

- Adaptable to existing infrastructures

- Opportunity to expand business: New products and New markets

- Higher quality products

Stage of Development

The technology is an innovative bioprocess that has been validated in a lab environment for treating water, fruit juices, wine, beer and milk. Validation in an industrial environment is the next step in our schedule to ensure the effectiveness of our process.

Partner Search

FOOD INNOVATION RI is seeking for Partners with the capacities to develop this technology. The ideal Partner shall be a food equipment manufacturer or a liquid food producer eager to further develop this technology in a relevant and operational environment. Alternative options may also be considered.

Offered by

Department of Chemistry, University of Patras, University Campus 26504 Rio Achaia, Greece

Contact

Prof Athanasios KOUTINAS

This email address is being protected from spambots. You need JavaScript enabled to view it.

Food Chemistry and Biotechnology Group